Multiple fields of expertise with myriad applications

At Cybernetix we are specialists in non-destructive technologies. Our offer for continuous and periodic testing of industrial structures and materials allows you to detect, identify and monitor damage to equipment.

Our experts apply multiple non-destructive testing methods: acoustic emission, ultrasonics, infrared thermography and ultrasonic technologies.

We apply multiple non-destructive testing methods: acoustic emission, ultrasonics, infrared thermography and ultrasonic technologies.

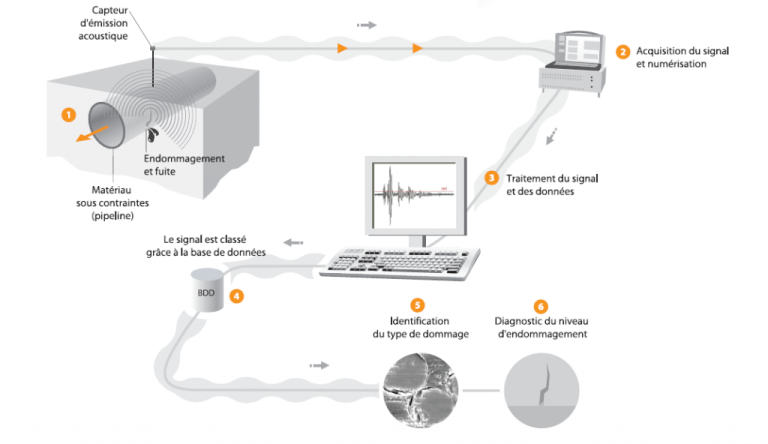

Acoustic Emission

The acoustic emission method is particularly effective in the detection and tracking of corrosion, cracks and breakages within in-use materials and equipment. Signals analyzed in real time can identify the nature and location of damage as well as its evolution.

The acoustic emission technique is field-proven and adaptable. It can be used for monitoring both materials and structures. Our teams can use it to test storage tanks, pressure equipment, and pipelines. It is also perfect for corrosion monitoring and online control of industrial processes.

Storage tank and pressurized equipment testing

By using the acoustic emission methodology for testing storage tanks and pressurized equipment, you both avoid costly shutdowns and benefit from very early stage defect detection.

Cybernetix' experts monitor and diagnose your installations via non-intrusive sensors while your operations continue as normal. Using advanced algorithms, our teams can accurately diagnose the presence of cracks, corrosion or leakage, even in inaccessible areas of pressurized equipment such as the bottom of storage tanks.

Ultrasonic Technologies

Detection. Location. Evaluation. Monitoring.

Ultrasonic technologies are ideal for testing materials and their coatings for damage and degradation. We provide a wide range of services, from feasibility studies to the development of innovative ultrasonic methodologies for materials with complex structures. We arere experts in both conventional and phased array technologies. Moreover, our laboratory has at its disposal immersion tanks to control flat or cylindrical pieces.

Active Infrared Thermography

Based on the analysis of heat fluxes emitted by samples, Active Infrared Thermography saves time and reduces control costs on both laboratory samples and large industrial parts. It's fast, contactless, and compatible with numerous materials for the detection of surface or subsurface defects.

Infrared requires no preparation of samples before or after inspection and has less environmental impact than techniques such as dye penetrant testing and magnetic particle testing. It also allows control over parts with a disadvantageous surface condition due, for example, to rust or dust.

At Cybernetix we leverage thermal stress experts and best-in-class R&D equipment to offer a wide range of services.

- Feasibility tests

- Defectology and expertise

- Monitoring of process and mechanical tests

- In-line control (quality, process, manufacturing, etc.)

Electromagnetism

Electromagnetic non-destructive technologies use electric currents and magnetic fields to observe the electromagnetic response of tested materials. They are used to detect and measure faults, thickness, electrical conductivity, and bond and weld integrity.

These advanced techniques require no coupling medium, and they don't even need to be in contact with the surface scanned. Defects can be located and evaluated in a way that is easily repeatable, making it possible to produce records that are long-lasting and open to analysis over time. The use of computerized systems for data acquisition and analysis makes results interpretation highly reliable.

We offer strong know-how in developing and qualifying these methods. We have particular expertise in designing complete systems for underwater inspection.

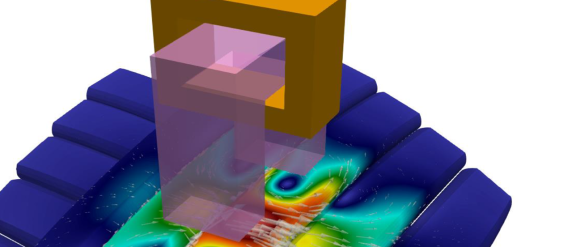

Guided waves

Guided waves are mechanical stress waves that propagate in long structures while guided by its boundaries. These boundaries allow the waves to travel a very long distance with little energy loss. Ultrasonic Guided Waves reflect back and forth on the boundaries of the waveguide, leading to interference phenomena (that could be constructive, destructive or intermediate).

Therefore interferences can be analyzed to assess the health of structures. Around a hundred meters of structures can be inspected from a single location and it is also suitable for inspection of inaccessible areas.

Get in touch

Do you want to speak to our team?

Browse our locations info or send a message using our contact us form: